Most offices look perfect on opening day. Six months later, they’re noisy, hard to manage, and full of daily friction. The problem isn’t design—it’s operational planning. Companies that skip acoustic treatment, underestimate meeting room needs, and choose pretty materials over durable ones pay for it through constant retrofitting and employee frustration.

Many offices look perfect on opening day.

Six months later, they’re noisy, inefficient, and frustrating to manage. The problem usually isn’t design—it’s operational planning. Or more accurately, the complete absence of it.

Here’s the pattern: Companies hire an interior designer who creates beautiful renders. Leadership approves based on aesthetics. Construction happens. The space photographs well. Then people actually start working there, and the problems surface.

Meeting rooms that looked sleek in walkthroughs turn out to be echo chambers. The open floor plan that won design awards becomes impossible to concentrate in. That custom pantry can’t handle fifty people trying to grab lunch at once. The HVAC system that was “adequate for the square footage” can’t keep up when eighty people show up on collaboration days.

This isn’t about bad designers or cheap construction. It’s about optimizing for how spaces look instead of how they’ll perform under actual use.

Visual Design vs Functional Design: What Actually Gets Prioritized

Walk through most office fit-outs and you’ll see where the budget went: feature walls, branded reception areas, Instagram-worthy breakout zones, designer furniture.

What you won’t see: proper acoustic treatment, adequate electrical capacity planning, maintenance access panels, sufficient meeting room inventory, durable materials that won’t need replacement in eighteen months.

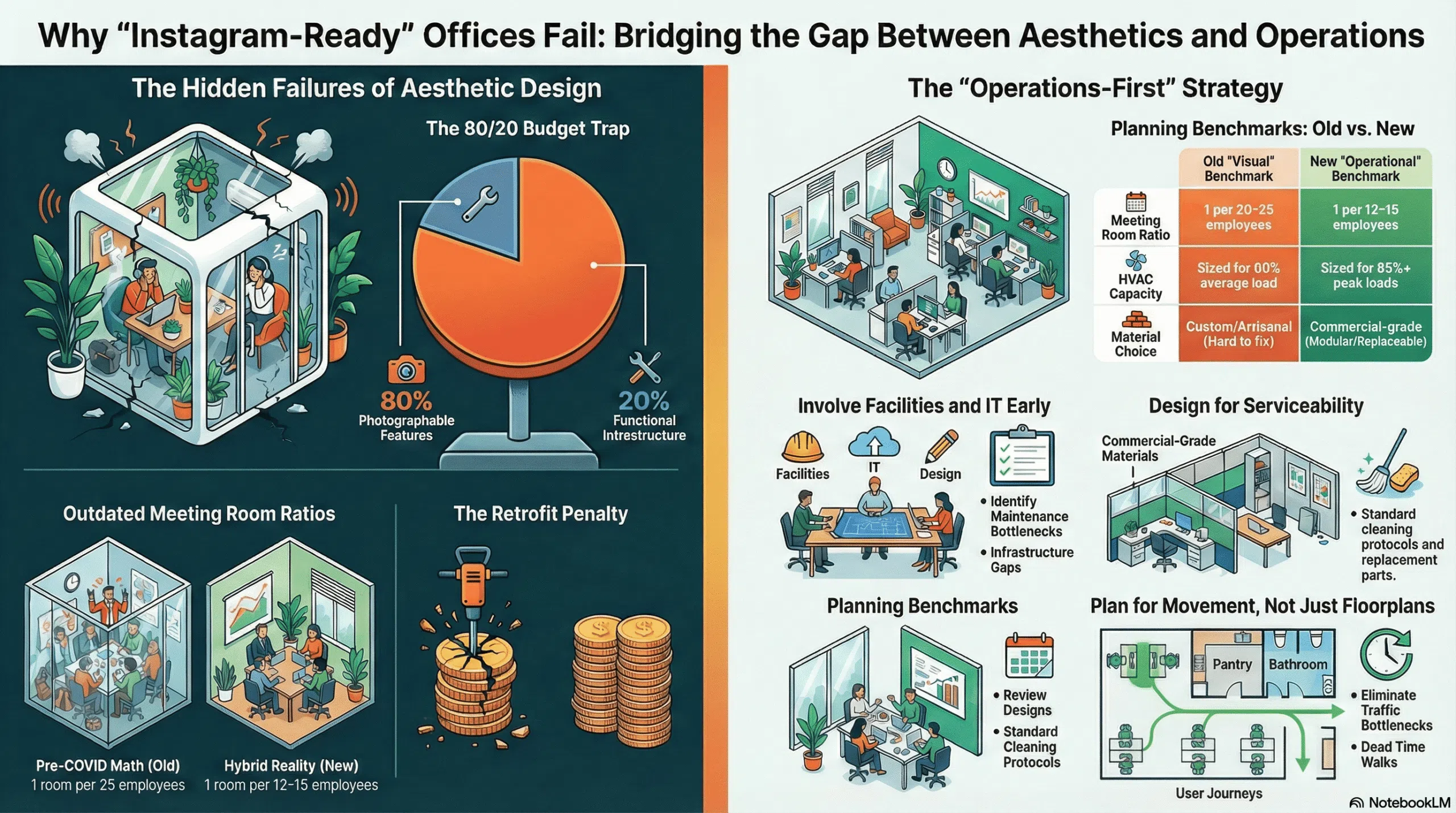

The honest truth is that most fit-out projects allocate 80% of attention and budget to things you can photograph, and 20% to things that make the office actually work. Then everyone acts surprised when operations struggle.

Here’s what gets missed:

Acoustics get value-engineered out of the budget. Ceiling baffles cost ₹200-400 per square foot. Sound-absorbing panels for walls run ₹150-300 per square foot. Proper door seals and acoustic glass add 15-20% to meeting room costs. These aren’t visually dramatic, so they’re the first things cut when the fit-out goes over budget.

Result? You spend ₹1.2 crores on a beautiful office, then spend another ₹15-20 lakhs six months later installing acoustic solutions because nobody can think.

Climate control gets sized for average occupancy, not peak loads. The HVAC consultant calculates based on 60% attendance because that’s what the hybrid policy says. But when teams coordinate to come in Tuesday-Wednesday-Thursday, you’ve got 85% attendance on those days. The system can’t handle it.

Summer afternoons become unbearable. Half the office complains it’s too cold, the other half is sweating. The thermostat becomes a negotiation point.

Meeting room inventory gets planned using pre-COVID math. The old formula was one meeting room per 20-25 employees. That worked when people came to the office for individual work and occasionally met.

Hybrid work flipped this. People now come to the office specifically for collaboration and meetings. You need one meeting room per 12-15 employees, maybe even tighter. Planning with old ratios means you’ve built a meeting room shortage into your design from day one.

Materials get chosen for aesthetics, not durability. That beautiful reclaimed wood reception desk? Can’t take daily wear. The artisanal concrete conference table? Already has cracks and stains. Custom fabric on chairs? Shows dirt immediately and can’t be cleaned properly.

You chose materials that photograph well, not materials that last. Now you’re replacing things that should have a 7-10 year lifespan after 18-24 months.

The companies that avoid these problems design for operations first, aesthetics second. They ask: “How will this actually perform when fifty people are here during peak hours?” Not: “How will this look in the portfolio shots?”

The Operational Problems That Surface After Handover

Let’s walk through what actually fails, in roughly chronological order after move-in.

Week 1-2: Acoustic Issues

That open floor plan looked collaborative in the renders. In practice, it’s chaos.

Phone calls overlap with team discussions. Sales calls happen ten feet from engineers trying to debug code. The meeting rooms with glass walls contain absolutely nothing—sound bounces around like you’re in a bathroom.

Everyone buys noise-cancelling headphones within the first month. Focus work becomes impossible without them. Introverts start working from home more because the office is just too loud.

Why this happens: Acoustic treatment doesn’t look like anything in photos. Hard surfaces (glass, concrete, metal) look modern and clean. They also reflect sound perfectly. Soft surfaces (fabric, wood, acoustic panels) absorb sound but don’t photograph as dramatically.

Most designers optimize for visual impact. Acoustics become an afterthought.

Month 1-2: Climate Control Wars

The HVAC works fine when 40 people are in the office. When 70 people show up, it struggles.

The server room side of the office runs cold (needs cooling). The window-adjacent workstations cook in afternoon sun. The interior zones have no natural light and feel stuffy. There’s one thermostat controlling three different microclimates.

Nobody’s comfortable. Facilities gets constant complaints. Portable fans appear on desks. People bring sweaters to handle the AC.

Why this happens: HVAC sizing requires predicting actual usage patterns, not reading the hybrid policy document. If your policy says “3 days in office” but Tuesday-Wednesday-Thursday become the de facto office days, you need to size for peak, not average.

Plus, companies cheap out on zoning. Proper zoned climate control costs 30-40% more than single-zone systems. So you get one thermostat trying to serve an entire floor with wildly different cooling needs.

Month 2-3: Meeting Room Shortage

You have six meeting rooms for one hundred people. The planning math said that was fine.

In practice, those rooms are booked solid from 10 AM to 5 PM every day. Teams fight over them. People schedule fake meetings to reserve rooms. Important client calls happen in stairwells because nothing’s available.

Why this happens: Hybrid work changed meeting patterns completely. Pre-COVID, people came to the office for desk work and occasionally met. Post-COVID, people come to the office for meetings and collaboration.

If you designed your meeting room inventory based on 2019 utilization patterns, you built in a structural shortage.

Month 3-6: Maintenance Complexity

The custom millwork starts showing wear. The branded feature wall needs touch-ups, but the original vendor is booked months out. The designer-spec furniture has a broken part, but there are no replacement components available.

Cleaning takes twice as long because the beautiful geometric ceiling panels trap dust in hard-to-reach spots. The mixed-material flooring requires three different maintenance protocols.

Why this happens: Nobody asked “How do we maintain this over five years?” during design. The conversation focused on how things look, not how they’ll age or what happens when things break.

Maintenance complexity compounds. What should cost ₹40,000 monthly in janitorial now costs ₹75,000. Simple repairs become procurement nightmares because nothing is standard.

Month 6-12: Layout Friction Becomes Obvious

The pantry is too small for lunch-hour traffic. There’s a chokepoint in the corridor between workstation zones. The bathrooms are too far from half the floor—people waste 10 minutes per day just walking.

Storage wasn’t planned, so boxes pile up in corners. The beautiful open shelving doesn’t actually hold anything useful. Personal items accumulate on desks because there’s nowhere else to put them.

Why this happens: Layouts get designed in 2D floor plans, not by simulating actual movement patterns. Nobody mapped user journeys: “Where does someone arriving at 9 AM actually go? What route do they take to meetings? How often do they need to access storage?”

The result is a space that works on paper but creates friction in practice.

Why Maintenance Gets Underestimated

Every company budgets for construction and fit-out. Almost nobody properly budgets for ongoing maintenance complexity.

Here’s what actually happens with materials that prioritize aesthetics over serviceability:

Custom finishes require specialized maintenance. That exposed concrete ceiling with custom staining? You can’t just repaint it when it needs refreshing. You need to bring back the original contractor who knows the specific mix and technique. They’re expensive and booked months out.

The reclaimed wood feature wall? It’s actually ten different wood species with custom finishes. Normal cleaning products damage it. You need specialized care, which means higher ongoing costs.

Complex geometries increase cleaning time. Open shelving looks minimal and modern. It also collects dust on every surface. Those geometric acoustic panels? Dirt accumulates in crevices that are hard to reach.

The beautiful terrazzo-style flooring? It’s actually three different materials with different porosity. Cleaning requires three separate processes and products. What should take sixty minutes now takes ninety.

Janitorial contracts get priced based on square footage and complexity. The more complex your finishes, the higher your ongoing costs.

Furniture chosen for design awards doesn’t hold up to daily use. Conference room chairs that won design competitions fall apart after eighteen months of actual use. The minimalist desk system can’t be reconfigured without special tools. Replacement parts aren’t available because the manufacturer has moved on to new designs.

Now you’re stuck either living with broken furniture or replacing entire systems because you can’t get individual components.

IT infrastructure ages poorly when access wasn’t planned. Cable management looked clean on day one. Then teams reorganize, people move desks, you need to add drops for new equipment.

The raised flooring doesn’t have enough access panels in the right locations. Running new cables means disrupting entire rows of workstations. What should be a 30-minute job becomes a half-day project affecting a dozen people.

The companies that handle maintenance well design for serviceability from the start:

They choose materials that are durable and easily sourced. They plan for access—to cables, to mechanical systems, to areas that will need periodic maintenance. They specify furniture that’s modular and has available replacement parts. They think about who will clean this and how long it will actually take.

None of this makes portfolio photos more impressive. But it makes the office work for years instead of months.

How Poor Layouts Create Daily Friction

Layout problems are invisible in 2D floor plans. They become painfully obvious when people actually use the space.

Pantry placement determines traffic patterns. Put the pantry too close to focus work areas, and noise disrupts concentration constantly. Put it too far from workstations, and people waste time on coffee runs. Size it too small, and lunch hour becomes a crowded mess.

Most layouts optimize for making the floor plan look balanced. They don’t simulate peak-hour pantry traffic or think about noise propagation.

Bathroom proximity matters more than you think. If bathrooms are positioned so employees need to walk two minutes each way, that’s 8-10 minutes daily per person. Multiply by team size, and you’re losing real productivity.

Plus, the bathroom trip becomes a psychological barrier. People defer going because it takes so long. That’s not good for health or concentration.

Circulation paths create bottlenecks. That corridor between workstation rows looked fine in the floor plan. In practice, when thirty people are moving around during peak hours, it’s a traffic jam.

The single entrance to the collaborative zone becomes a chokepoint during all-hands meetings. The pathway from reception to the main work area forces everyone through the quiet focus zone, creating constant disruptions.

Storage gets completely forgotten. Where do teams put old marketing materials? Office supplies? Seasonal decorations? Personal items that don’t belong on desks?

Without planned storage, clutter accumulates wherever there’s space. The beautiful minimal aesthetic degrades into boxes stacked in corners and items piling up on “temporary” shelving.

The fix isn’t complicated—you just have to actually map how people move and where things get stored. Walk through the daily rhythms: morning arrival, coffee breaks, lunch, afternoon meetings, end of day. Identify where traffic concentrates. Plan accordingly.

Most designers don’t do this. They arrange furniture to make floor plans look balanced. Then real usage patterns create friction the design never anticipated.

What Experienced Operators Plan For Upfront

The companies that avoid these operational failures approach fit-outs completely differently.

They start with operational requirements, not aesthetic goals.

They ask different questions during planning:

-

How many people will actually be here during peak days, not what the policy says?

-

What activities will they perform, and what infrastructure does that require?

-

Where will noise concentrate, and how do we manage it?

-

How will we clean and maintain this in year three, not just month one?

-

What breaks, what gets replaced, and where do we source parts?

They build in redundancy and buffer capacity:

-

Extra meeting rooms beyond the formula (you can always repurpose one; you can’t easily add more)

-

HVAC sized for peak loads plus 15-20% buffer

-

Electrical capacity for future equipment, not just current needs

-

More storage than you think you need (teams always accumulate more stuff)

They involve facilities management before design is finalized. The operations team knows what actually breaks, what’s hard to maintain, what creates daily problems. Getting their input during design prevents problems, not just patches them after construction.

They test acoustic performance before finalizing finishes. Some firms actually build mockups of spaces and test how sound behaves. You find out that glass conference rooms need acoustic treatment before you’ve installed ten of them.

They choose materials for durability and replaceability. Commercial-grade furniture with available parts. Flooring that can take daily traffic. Finishes that age well and can be refreshed without specialized contractors.

None of this is expensive or complex. It just requires asking operational questions during design, not as an afterthought.

The Real Cost of Getting This Wrong

When offices fail operationally, the costs show up in ways that don’t appear in facility budgets:

Retrofitting solutions costs 2-3x what building correctly would have cost. Installing acoustic treatment after construction means working around existing systems, coordinating with occupied spaces, and paying premium rates for change orders. You spend ₹15-25 lakhs fixing acoustic problems that would have cost ₹8-12 lakhs to prevent.

Employee frustration compounds over time. The noise issues you tolerate in month one become resignation factors by month six. People choose to work from home not because they prefer it, but because the office is too frustrating to use.

You lose the collaboration benefits you built the office for. Hybrid work patterns were supposed to bring teams together—but not if the office itself drives people away.

Operational friction erodes the culture you’re trying to build. Daily annoyances add up. Fighting for meeting rooms. Struggling to concentrate. Dealing with temperature fluctuations. Navigating poor layouts.

These aren’t major problems individually. But they create constant low-grade friction that makes work harder than it should be.

Maintenance costs run higher permanently. Once you’ve chosen complex finishes and custom solutions, you’re locked into higher ongoing costs. Switching would require another fit-out. So you just pay the premium forever.

The companies that succeed long-term treat office fit-outs as operational infrastructure, not interior design projects. They design for how teams actually work, not how spaces photograph.

How to Approach Your Next Office Project

If you’re planning a new office or evaluating existing office space in Gurgaon, here’s what changes the outcome:

Map actual usage patterns before finalizing design. Don’t just read the hybrid policy—look at calendar data. Which days do people actually come in? How long are meetings? What gets scheduled back-to-back? Design for observed behavior, not policy documents.

Test assumptions against real conditions. Before committing to an open floor plan, visit other offices using that layout. Talk to people working there. Is it actually as collaborative as it looks, or do people just wear headphones constantly?

Budget for the unglamorous infrastructure. Acoustic treatment, proper HVAC zoning, adequate meeting room inventory, durable materials. These aren’t portfolio pieces. They’re what makes everything else work.

Involve operations early. Get facilities, IT, and office management into design conversations before construction starts. They know what creates problems. Their input prevents issues, doesn’t just react to them.

Plan for change and maintenance. Your team will grow. Layouts will need adjustment. Equipment will break. Design for modification and maintenance from the start.

The offices that work long-term aren’t the ones that win design awards. They’re the ones where people can actually get work done without fighting the space.

For companies evaluating managed office space in Gurgaon, one advantage is that operational lessons are built into the design from the start. You benefit from what’s already been learned through trial and error across multiple fit-outs.

If you’re planning office space and want to avoid common operational failures, get in touch with AIHP to discuss how to design for actual usage patterns. For frameworks on space planning and operational efficiency, download The Ultimate Guide to Managed Office Spaces.

Frequently Asked Questions

Underestimating meeting room requirements for hybrid teams. The old formula (one room per 20-25 employees) assumed people came to the office for individual work and occasionally met. Hybrid work flipped this—people now come to the office specifically for meetings and collaboration. You need one meeting room per 12-15 employees, maybe tighter depending on your meeting culture. Companies that use pre-COVID planning ratios build a meeting room shortage into their design from day one, then spend months dealing with booking conflicts and frustrated teams.

Plan for ₹250-450 per square foot of workspace area if you're doing it properly. This includes ceiling baffles or acoustic tiles, wall panels for high-traffic zones, proper door seals for meeting rooms, and acoustic glass where needed. Many companies try to cut this cost during construction, then spend ₹15-25 lakhs retrofitting solutions six months later when the noise becomes unbearable. Acoustic treatment isn't visually dramatic, so it's often the first thing value-engineered out of budgets—and the first thing that has to be added back.

Because they're sized for average occupancy, not peak loads or actual usage patterns. If your hybrid policy says "3 days in office" but everyone coordinates to come Tuesday-Wednesday-Thursday, your peak occupancy is much higher than your average. Add in server rooms, afternoon sun loads through windows, and internal heat from equipment, and suddenly the system can't keep up. Proper HVAC design requires predicting real usage patterns and building in 15-20% buffer capacity. Single-zone systems (one thermostat for an entire floor) are cheaper but create temperature wars between different areas with different cooling needs.

Avoid anything custom or artisanal that can't be easily replaced or maintained. Reclaimed wood looks great but shows wear quickly and can't be touched up with standard finishes. Polished concrete surfaces stain easily and require specialized care. Delicate fabrics on furniture in high-use areas (reception, pantry seating) get dirty fast and can't be properly cleaned. Custom millwork has no replacement parts when something breaks. Stick with commercial-grade materials that are designed for daily use, have available replacement parts, and can be maintained by standard facility teams—not specialized contractors who cost 3x as much.

Map user journeys and simulate peak-hour flows before finalizing the layout. Walk through the daily patterns: Where does someone arriving at 9 AM go? What's their route to meetings? How often do they access pantry, bathrooms, storage? Where do traffic jams form when 30 people are moving around? The best operators visit similar offices and observe how people actually use spaces—not how designers say they'll be used. You can also build rough mockups with temporary walls to test circulation paths and sight lines before committing to permanent construction.